Check out this brick vault I'm building!

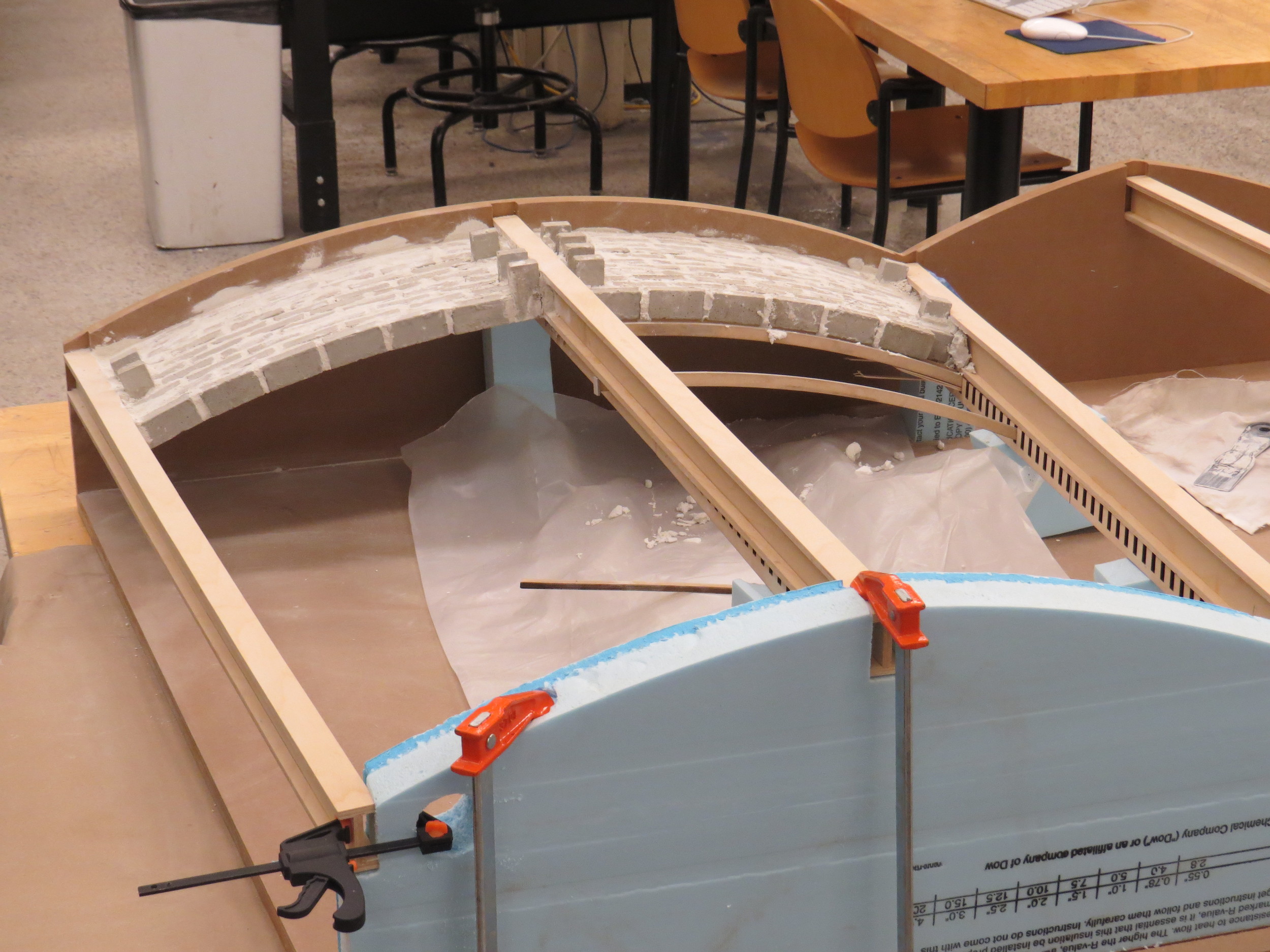

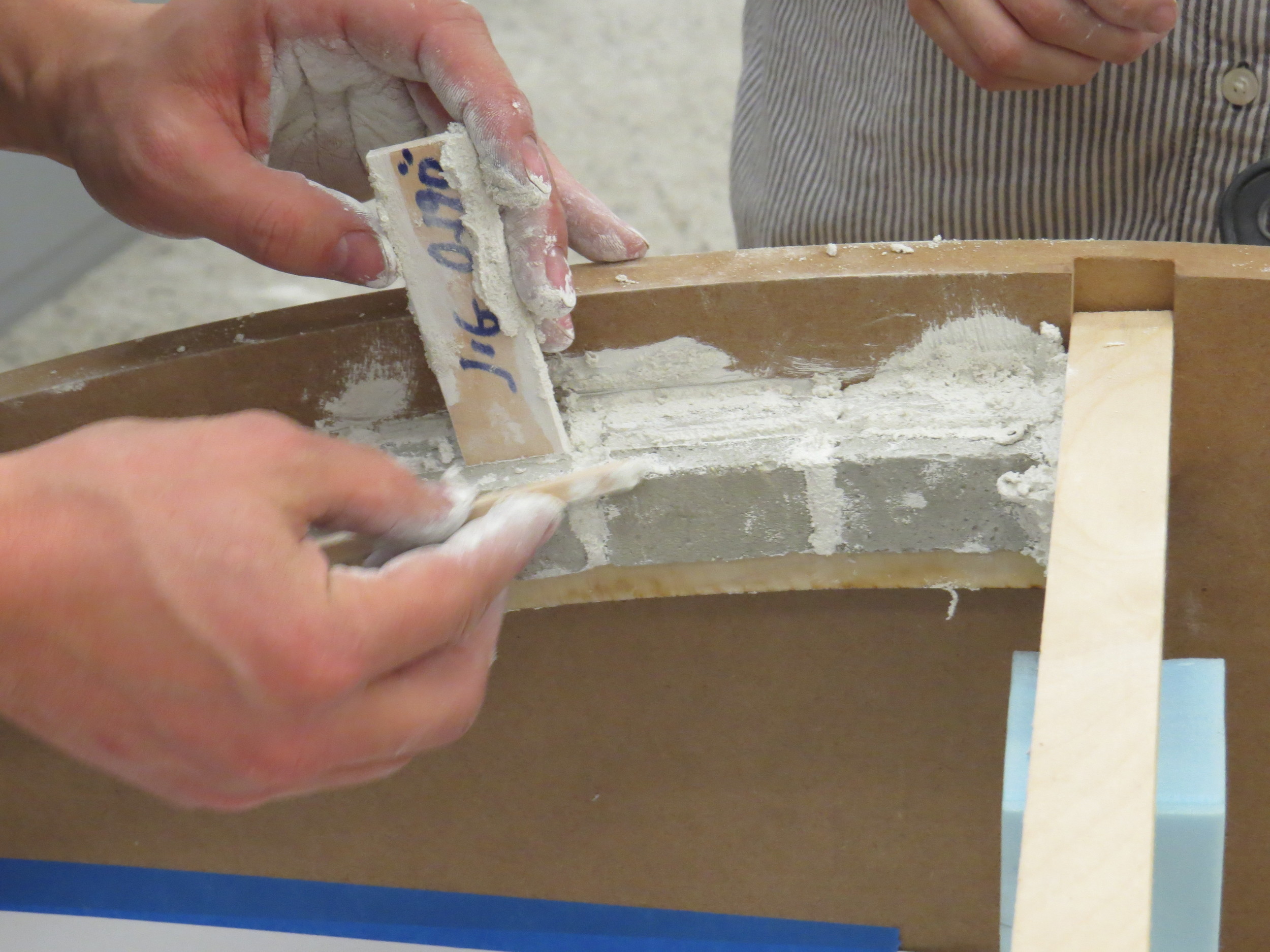

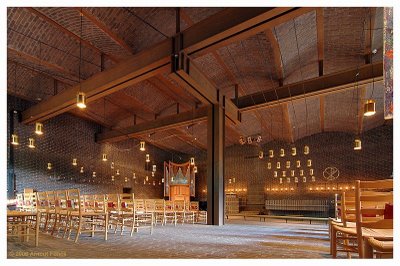

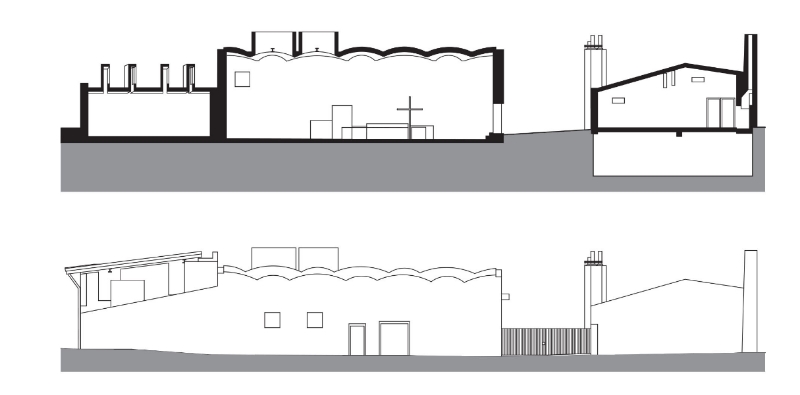

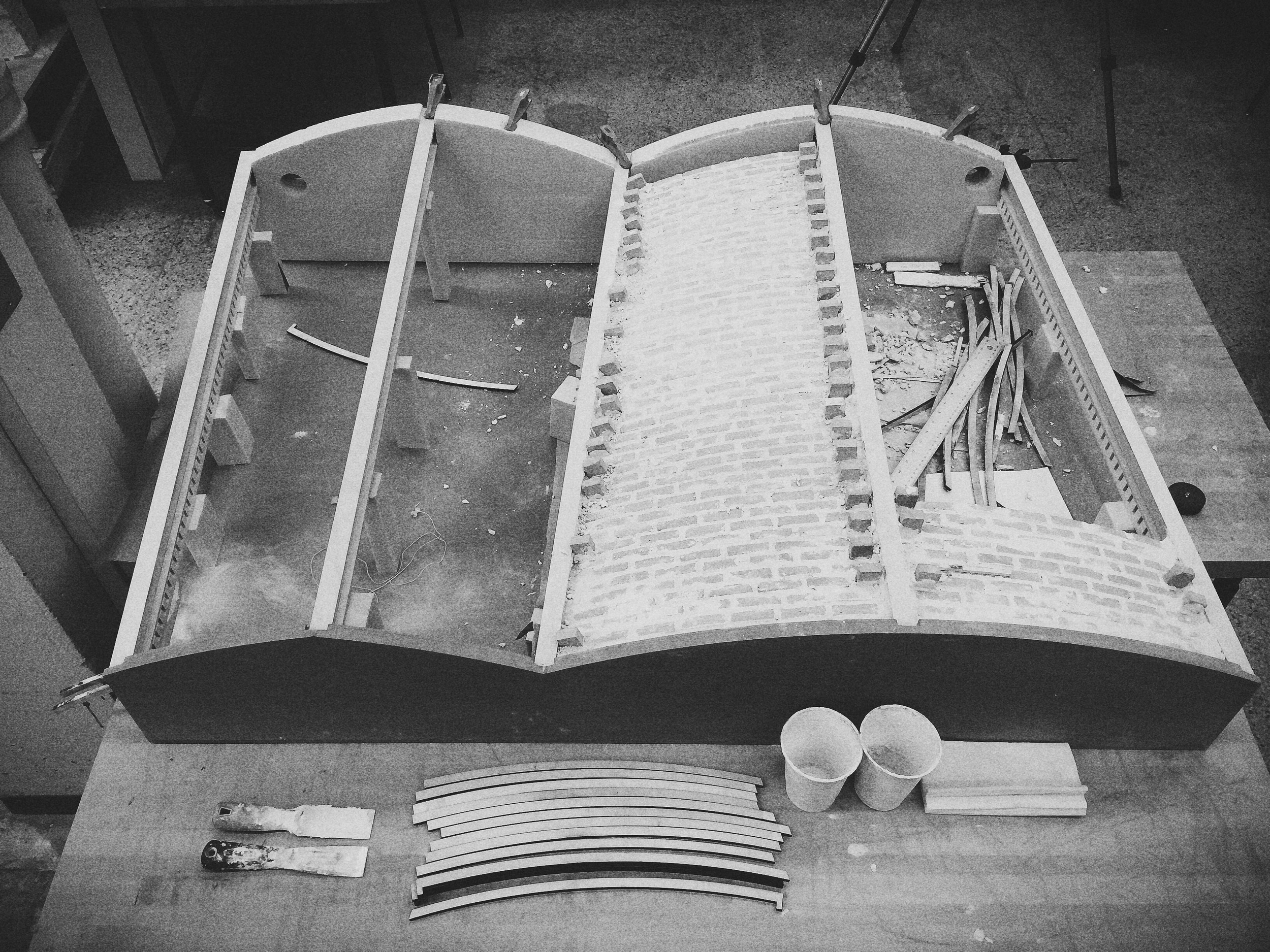

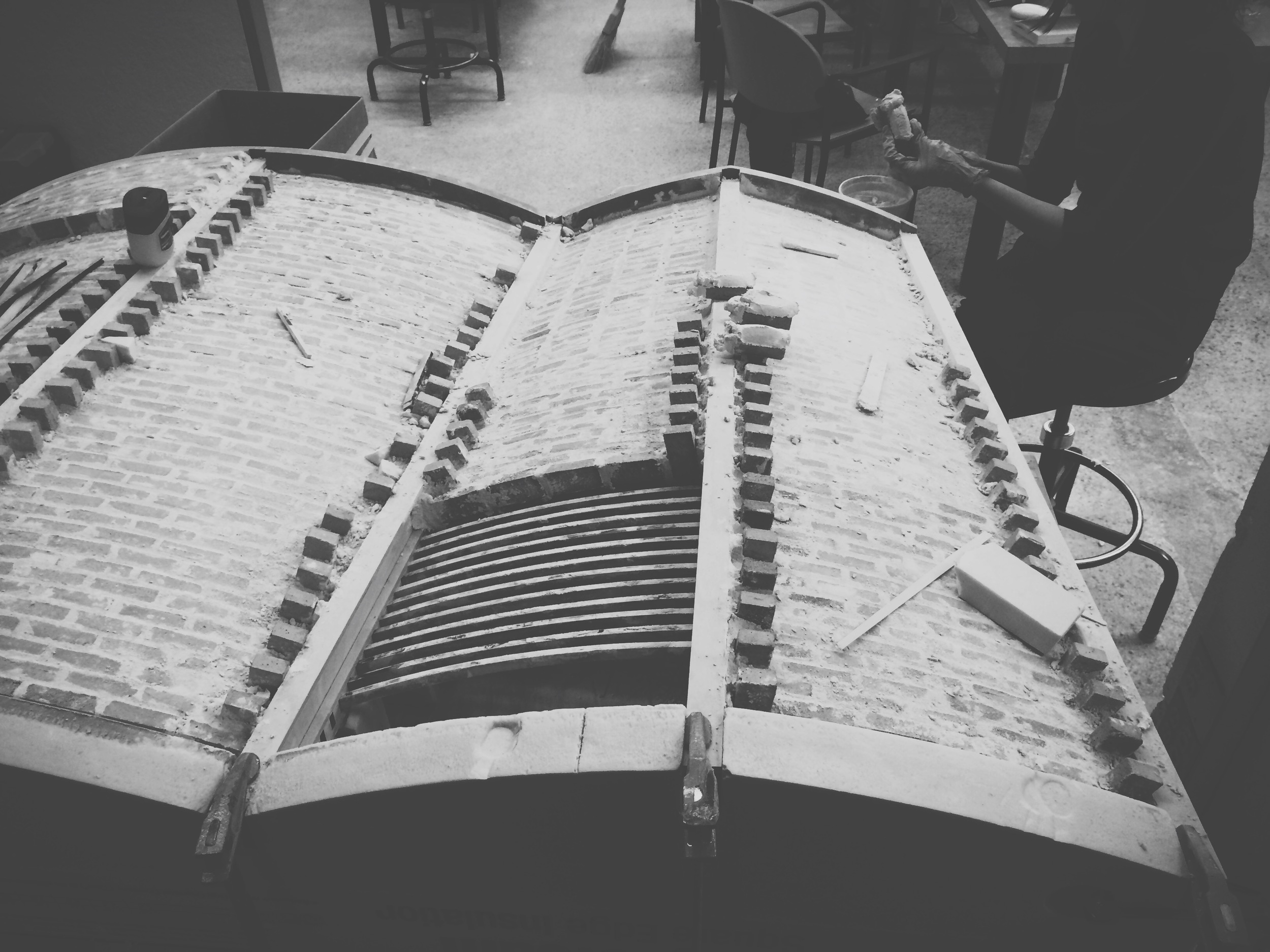

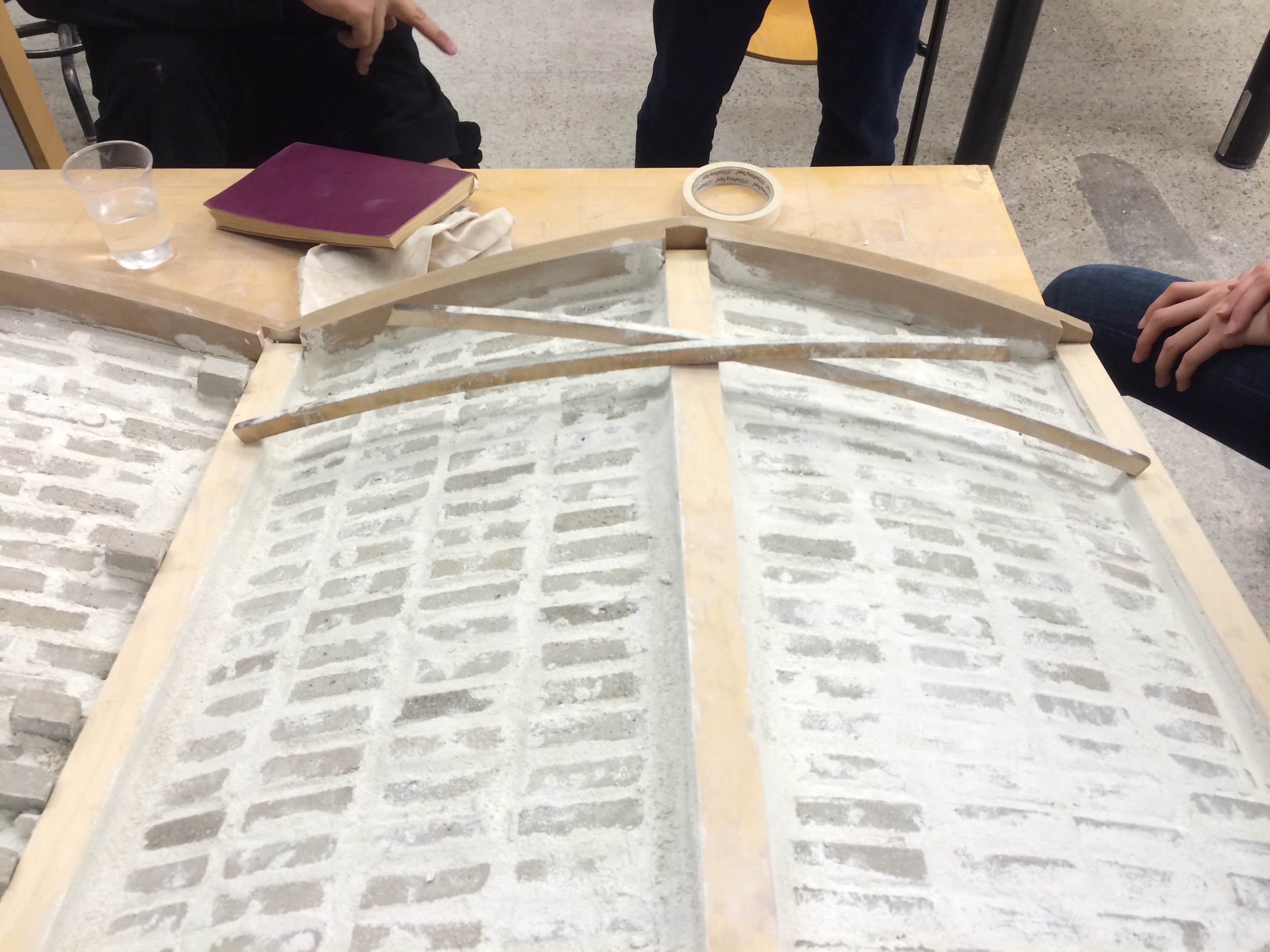

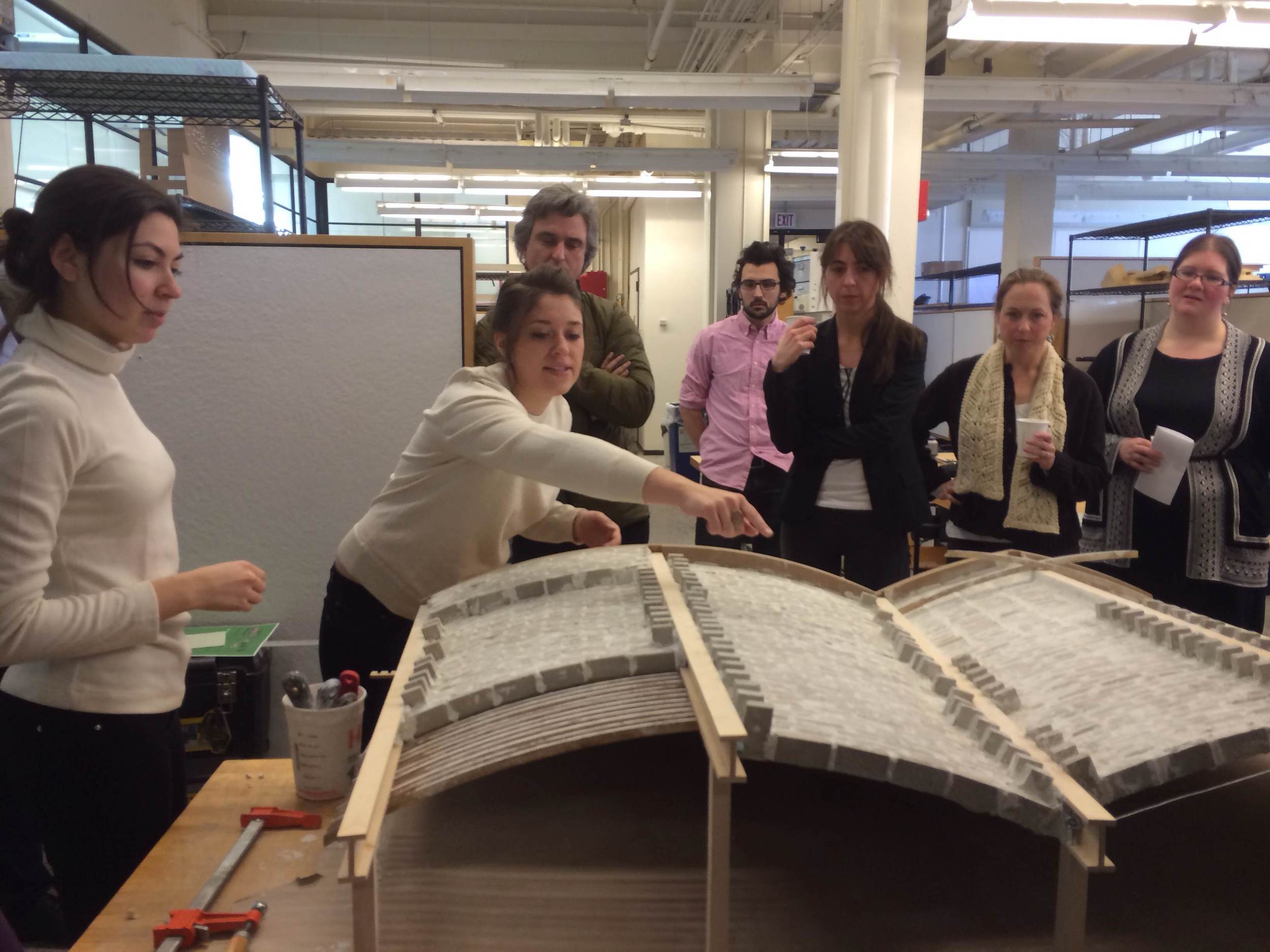

In this semester's studio we are starting our masonry research by studying the brick work in the 1966 Church of St Peter in Klippan, Sweden by architect Sigurd Lewerentz. We are modeling a possible construction method of a portion of the roof based on what we know from photos and drawings. The vault is a series of intersecting extrusions of one radius along a beam. Because the vault is an extrusion and not a cone, one could use a reusable formwork with a constant radius to build each arch. We are modeling how a mason might place these bricks on a removable wooden rib of that radius that notches into two temporary beams supported from the ground. Lewerentz never cut any bricks for this, but does turn the brick on its end for the effect of a "half brick." The adjustments are made in the mortar joints. There will be two layers of brick modeled here. It took us about 20 minutes to lay each course of brick....so in approximately 26 hours of work it will be "finished." Each bay will be an experiment of different building techniques, and will be in various stages of completeness to reveal the process.

It's amazing to me that such technology of construction method can be lost in history. Older buildings that do not have documentation on the details of formwork and construction leave us guessing and interpreting clues as to their method.

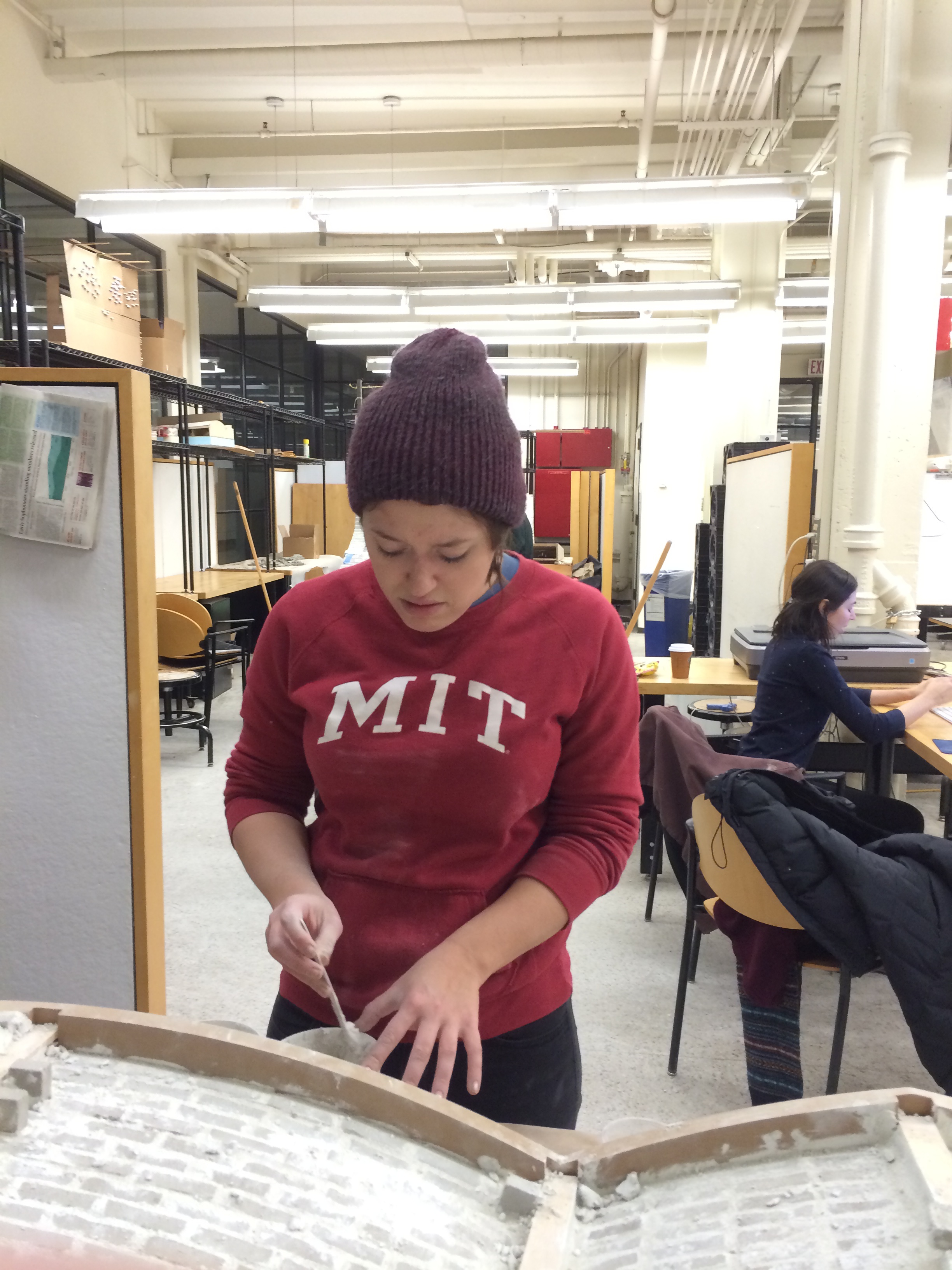

It's exciting to be building! This is what ultimately attracted me to MIT. We learn by making here. After all, our motto is Mens et Manus: Mind and Hand.

Bricks are at 1:4 scale, cast from Quikrete in rubber smooth-on molds. For mortar we are using joint compound. Base is constructed of milled MDF and plywood "I-beams." The blue foam is a stand in for a piece of acrylic to act as our cut plane. This is a 3-person group effort with David Miranowski and Elizabeth Galvez.

Click through the gallery below:

![dIAGRAMS SEQUENCE [Converted]vERTICAL2.jpg](https://images.squarespace-cdn.com/content/v1/528944dbe4b088c60f4c98fd/1394333430741-29V4IHN0O81276YPF8NN/dIAGRAMS+SEQUENCE+%5BConverted%5DvERTICAL2.jpg)